Test Methods and Specifications

Concrete Pavement Base

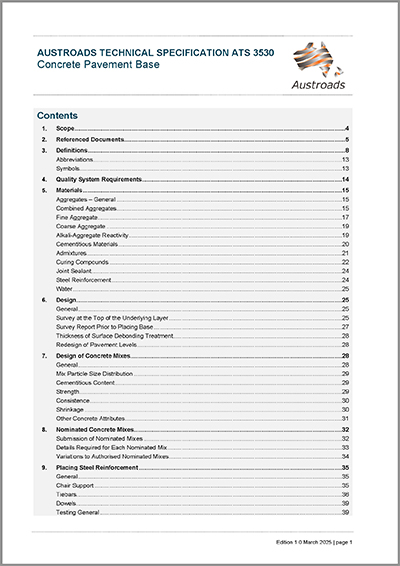

- Publication no: ATS-3530-25

- Published: 5 March 2025

- Edition: 1.0

- PDF (free) Download

Austroads Technical Specification ATS 3530 sets out the requirements for the supply of concrete and construction of the base (upper) layer of the following formats:

- plain concrete pavement (PCP);

- continuously reinforced concrete pavement (CRCP);

- jointed reinforced concrete pavement (JRCP); and

- steel fibre reinforced concrete pavement (SFCP).

The technical specification can also be downloaded as a Word document.

- 1. Scope

- 2. Referenced Documents

- 3. Definitions

- Abbreviations

- Symbols

- 4. Quality System Requirements

- 5. Materials

- Aggregates – General

- Combined Aggregates

- Fine Aggregate

- Coarse Aggregate

- Alkali-Aggregate Reactivity

- Cementitious Materials

- Admixtures

- Curing Compounds

- Joint Sealant

- Steel Reinforcement

- Water

- 6. Design

- General

- Survey at the Top of the Underlying Layer

- Survey Report Prior to Placing Base

- Thickness of Surface Debonding Treatment

- Redesign of Pavement Levels

- 7. Design of Concrete Mixes

- General

- Mix Particle Size Distribution

- Cementitious Content

- Strength

- Consistence

- Shrinkage

- Other Concrete Attributes

- 8. Nominated Concrete Mixes

- Submission of Nominated Mixes

- Details Required for Each Nominated Mix

- Variations to Authorised Nominated Mixes

- 9. Placing Steel Reinforcement

- General

- Chair Support

- Tiebars

- Dowels

- Testing General

- Protective Coatings

- Bending of Steel Reinforcement

- Welding

- Lapped Splices

- Mechanical Splices

- Storage

- 10. Production and Transport of Concrete

- General

- Production Mixes

- 7-Day Compressive Strength

- Frequency of Moulding of Flexural Test Specimens

- Flexural Strength Test Specimens

- Assessment of 28-day Flexural Strength

- Process Control Charts

- Mixing, Transport, Consistence and Air Content

- Mixing Time

- Mixer Uniformity Testing

- Admixture Addition

- Incorporation during initial batching

- Addition of admixtures to a mobile mixer after Completion of Batching

- Batch Delivery Docket

- Consistence (Slump)

- Minimum Frequency of Routine Testing - Tipper Delivery

- Minimum Frequency of Routine Testing - Mobile Mixer Delivery

- Retempering

- Forming Time

- Air Content of Concrete

- Transport of Mixes for Fixed-form Paving

- 11. Concreting Personnel

- General

- Paving Supervisor

- Paving Crew

- 12. Paving Concrete

- General

- Slipform (Mechanical) Paving

- Fixed-Form (Manual) Paving

- Placing and Paving Operations

- 13. Temperature

- Concrete Temperature

- Air Temperature

- 14. Prevention of Moisture Loss

- 15. Texturing of Surface

- General

- Hessian Drag and Brooming (Initial Texturing)

- Tining

- Texture Testing

- Sawcut Grooves

- 16. Curing

- General

- Materials and Equipment

- Application Rate

- Curing of Other Structural Concrete

- 17. Protection of Work

- Temperature

- Rain

- Anchor Slabs

- Trafficking of Base

- 18. Concrete Paving Trials

- General

- Acceptance of Trial Section

- 19. Joints and Edges

- General

- Joint Cleaning and Sealants

- Transverse Construction Joints

- Transverse Contraction Joints

- Isolation and Expansion Joints

- Longitudinal Joints

- Mismatched Joints and Re-entrant Angles

- Outer Edges

- 20. Kerb And Channel

- 21. Special Slabs

- Odd-shaped and Mismatched Slabs

- Anchor Slabs

- 22. Slab Anchors

- Slab Anchors

- 23. Traffic Islands and Medians

- 24. Conformity – Concrete Cracking

- 25. Conformity – Concrete Compaction

- Sub-Lot Delineation

- Conformity for Compaction – Fixed-form Paving

- Conformity for Compaction – Slipform Paving

- Moulding and Testing of Cylinders

- Core Specimens

- Frequency and Location of Coring for Compaction

- Locations of Coring for Compaction

- Repair of Core Holes

- Core Testing for Unit Mass

- Within-core Variability

- 26. Conformity – Concrete Compressive Strength

- Cylinder Strength Testing

- Core Strength Testing

- Assessment of Compressive Strength – Test Cylinders

- Assessment of Compressive Strength – Cores

- Correction Factors for Age and Shape

- 27. Conformity – Geometry and Thickness

- Alignment Tolerances

- Level Survey

- Thickness Assessment

- Conformity for Thickness

- 28. Conformity – Surface Profile

- Transverse Profile

- Longitudinal Profile

- 29. Conformity - Ride Quality

- Testing

- Incentives/Deduction for Pavement Roughness

- 30. Removal and Replacement of Concrete Base

- General

- Jointed Base

- Continuously Reinforced Concrete Pavement (CRCP)

- 31. Rectification of Finished Surface and Ride Quality

- 32. Steel Fibre Reinforced Concrete

- General

- Steel Fibres

- Fibre Dose Rate

- Steel Fibre Reinforced Concrete

- Consistence

- Shrinkage

- Air Content

- Batching, Mixing and Transport

- Nominated Concrete Mixes

- Texturing

- Conformity for Flexural Strength

- Conformity for Thickness

- Conformity for Compaction

- Representative Beam Unit Mass

- 33. Testing Procedures

- Mixer Uniformity

- Unit Mass of Cylinders and Cores

- Annexure A: Summary of Hold Points, Witness Points and Records

- Annexure B: Mixer Uniformity Testing

- B1 Mixer Uniformity Testing - General

- B2 Uniformity Testing of Continuous Mixers

- B3 Uniformity Testing of Central Batch Mixers

- B4 Uniformity Testing of Mobile Batch Mixers

- B5 Compliance for Uniformity

- Annexure C: Minimum Frequency of Testing

- Amendment Record

Related publications

ATS-3520-25

ATS-3550-25

ATM-000-25

Latest Test Methods and Specifications News