1.1.3 Development of Guides to Sprayed Sealing Practice

Expertise in sprayed sealing work largely developed within individual road agencies in Australia and New Zealand, leading to the production of comprehensive manuals articulating the practice in those particular organisations (e.g. Roads and Traffic Authority NSW (1997); Transit New Zealand, Road Controlling Authorities and Roading New Zealand (2005); VicRoads and Geopave (2004)).

The first attempt to produce a national guide was made with the publication of the Principles and Practice of Bituminous Surfacing – Part 1: Sprayed Work by the National Association of Australian State Road Authorities (NAASRA) in 1965. A companion volume referred to Plant Mix Work.

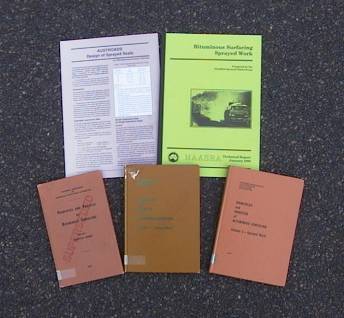

The 1965 guide was a simple overview of the selection, design and conduct of sprayed sealing work. Although rather basic, it was a popular publication, with a second edition in 1975 and reprints in 1980 and 1984. A third edition appeared in January 1989 as a technical report under the title of Bituminous Surfacing Sprayed Work (Figure 1.5).

Figure 1.5: Previous guides to sprayed sealing practice

Source: ARRB.

During the 1990s, it became apparent the published procedures for selection and design of sprayed seals were not keeping pace with increases in traffic (particularly heavy vehicles), and improvements in materials and equipment.

Changes in materials included introduction of crumb rubber and other polymer modified binders, commonly referred to as PMBs. Crumb rubber was one of the early polymers introduced in the early 1970s, based on a concept developed in the USA to utilise fine granulated scrap rubber from vehicle tyres. Other types of polymers have been introduced since. The use of PMBs enables a thicker bituminous membrane to be applied to resist reflection cracking in aged and/or cracked pavements.

Changes in road use arise particularly from increased wheel loads, tyre pressures and configuration of heavy vehicles as well as an overall increase in volume and speed of all vehicles. Increased demands on sprayed seals also arose from a desire to continue their use as a relatively economical treatment on a wide variety of road classes, and not just lightly trafficked rural roads.

A national working group was established to review sprayed seal design and performance. The initial outcome was a state-of-the-art review, published as Review of Sprayed Seal Design (NAASRA 1988). The working group commenced a long-term review of sprayed seal design and published, in brief format as an interim measure, the Design of Sprayed Seals in 1990. That design method was based on the best information available and retained the Hanson principles of aggregate voids related to traffic volume and aggregate ALD, but with more detailed advice on adjustments for different traffic effects, surface texture, embedment, absorption and aggregate characteristics.

National trials commenced in 1991 to evaluate a number of design criteria with the aim of further improving the reliability of sprayed seal design. The comprehensive review and trials of design factors related to sprayed seal performance took some time to complete. The performance of sprayed seals is sensitive to variations in traffic (particularly heavy traffic), aggregate characteristics (size, shape and wear characteristics), and to surface conditions relating to texture and embedment. It is also influenced by climate and binder properties. Some of these effects are only apparent after a long period of service. Hence, detailed observation of a large number of field trials over a lengthy period was required in order to enable sufficient data for valid statistical analysis. Development of suitable test procedures for design parameters and measurement of performance were an important part of the project.

The outcomes were initially published as the Austroads Provisional Sprayed Seal Design Method – Revision 2000 followed by Update of the Austroads Sprayed Seal Design Method in 2006, and Update of the Double/Double Design for Austroads Sprayed Seal Method in 2013.