4.3 Distress Modes

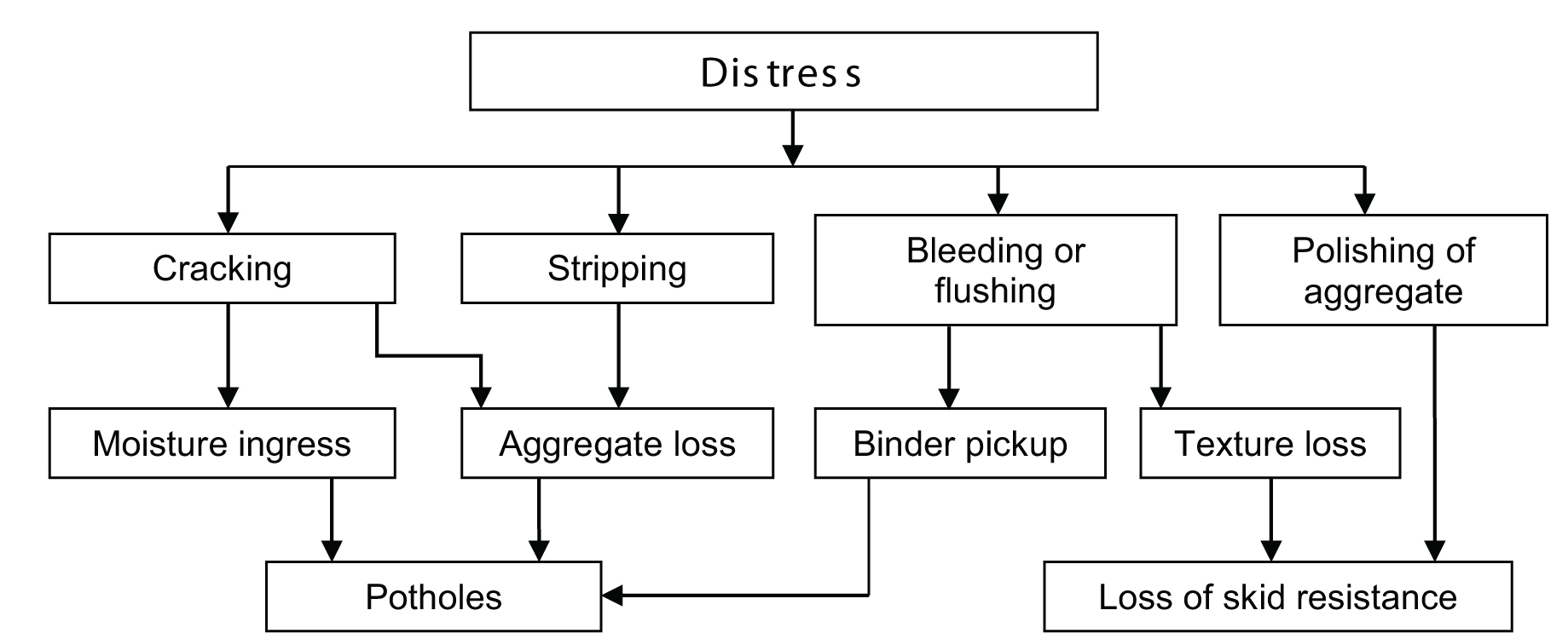

Sprayed seals are subject to a number of distress modes, which may operate independently or interact. The primary mechanisms are illustrated in Figure 4.1. The potential distress modes must be addressed when looking at the selection, design and whole-of-life cost analyses of surfacing treatments.

A further distress mode is that of shearing where surface stresses from turning or braking exceed the cohesive strength of the binder or the adhesive bond of the binder/aggregate or the seal/base (i.e. in extreme cases, sections of the seal may be peeled off). High shearing forces typically occur where there are significant volumes of turning vehicles such as at roundabouts, turning lanes or intersections. Seals using conventional bitumen do not have a high resistance to shearing forces and alternative seal treatments or asphalt may need to be considered where the circumstances apply.

Distress in sprayed seals may also occur because of deficiencies in underlying base materials.

Figure 4.1: Distress modes for sprayed seals