Appendix F 4.3 Embedment Allowance (Ae)

Initial treatments

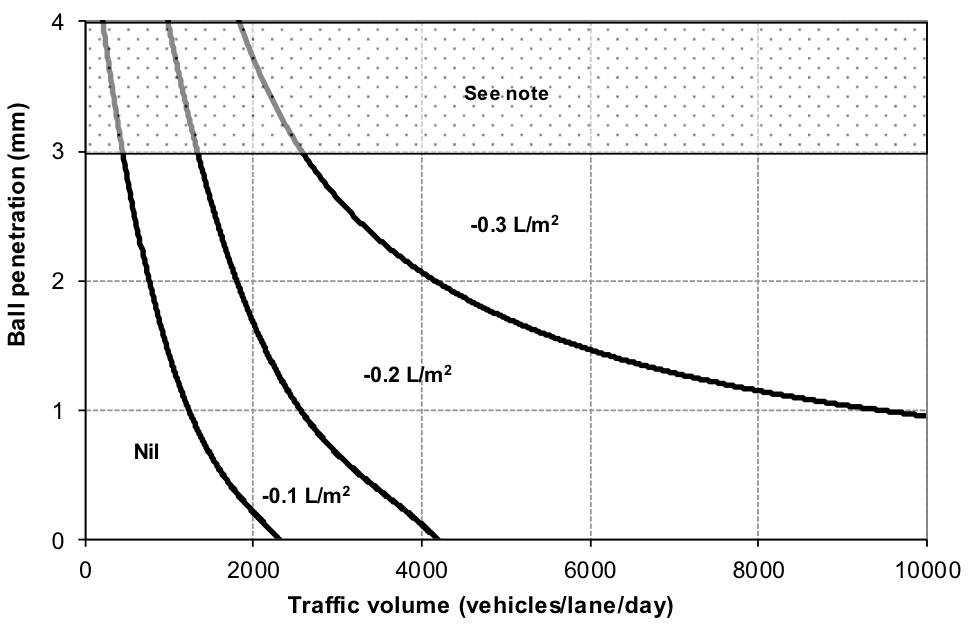

Typical embedment allowances (in L/m2) are shown in Figure F 7.

Figure F 7: Embedment allowance for initial treatments

Note: It is recommended that the following alternatives be considered where the ball embedment value exceeds 3 mm:

- If due to moisture, defer sealing to allow the surface to harden as it dries back. The surface should be retested once it has dried sufficiently.

- Apply a small aggregate seal as the first seal to act as an armour-coat and minimise the amount of embedment of the larger aggregate applied at a later date, say after about 12 months.

Reseals

Embedment of aggregate may occur in reseals:

- if there is free binder on the surface being resealed

- when applying a reseal over fresh asphalt or microsurfacing

- when applying a reseal over fresh maintenance patching.

Binder absorption by pavement

Initial treatments

Binder from a seal may drain into voids in the surface of the base course if these have not been adequately filled by a prime or initial seal. This is most likely to occur in sandy or silty rubble base materials (sandstone, limestone or silty gravels) in a hot dry climate.

It is strongly recommended that all new pavement surfaces should be primed or initial sealed. However, in some areas a seal is applied directly to the prepared granular pavement and the following binder absorption allowances provide a guide for use in these situations:

| allow +0.1 to +0.2 L/m2 |

| allow +0.0 to +0.1 L/m2 |

| allow –0.1 to +0.1 L/m2 |

| For the use of chemical binders, refer to Austroads Guide Part to Pavement Technology Part 4D (Austroads 2006) |

Reseals

Binder absorption into the existing surface will seldom be a problem unless the existing surface is visibly open and porous.

Binder absorption by aggregate

Absorptive aggregates may fall into two general categories:

- Porous, e.g. sandstone, rhyolite etc.

- Vesicular (full of cavities), e.g. scoria, slags etc.

In general, binder absorption into aggregate is not applicable, but if an allowance is required, it does not usually exceed 0.1 L/m2.